In-Service Welding

In-Service Welding is specialized welding on a piping system that is flowing and/or under pressure.

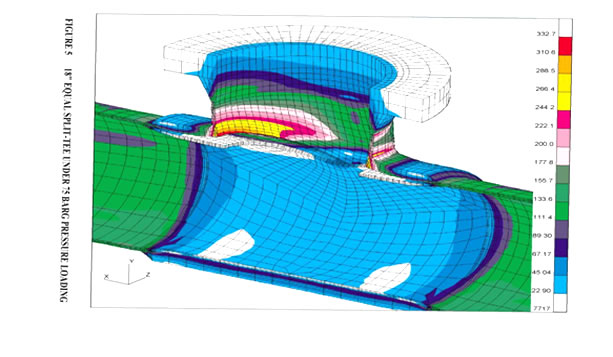

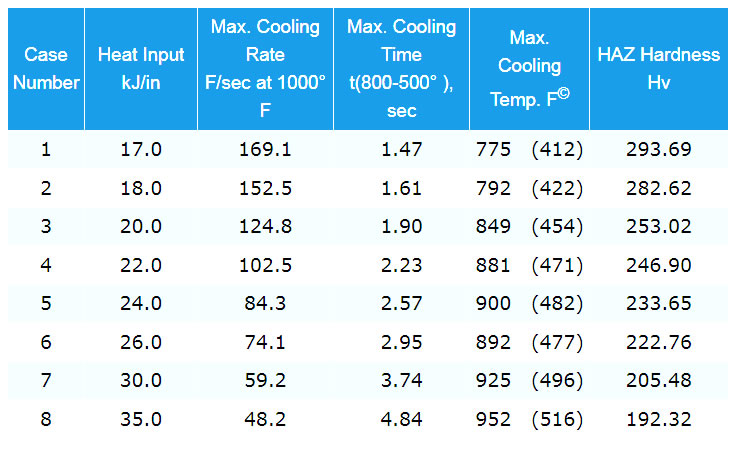

“Thermal Analysis” is carried out to mitigate the risk involved by calculating a) HAZ hardness value b) Cooling Rate c) Pipe Inside Temperature. These values are used to control the risk of burn-through and in determining a suitable Welding parameters / Procedure for In-Service Welding.

Our Standard Welding Package :

Thermal Analysis

PMI Service

The most critical variable for determining the crack susceptibility during and after welding is the chemistry of the material. The percentages of Carbon (C), Manganese (Mn), Chromium (Cr), Molybdenum (Mo), Vanadium (V), Nickel (Ni), and Copper (Cu) are used to calculate the Carbon Equivalent (CE), value of a material.

It is considered to be best practice to determine the actual CE value of a pipeline to confirm the applicability of existing welding procedures or to develop new welding procedures. We provide PMI services (at site) for the pipeline where Carbon Equivalent not available, we use portable spectrograph equipment and / or metal shaving equipment to analyse the CE value of a pipe.