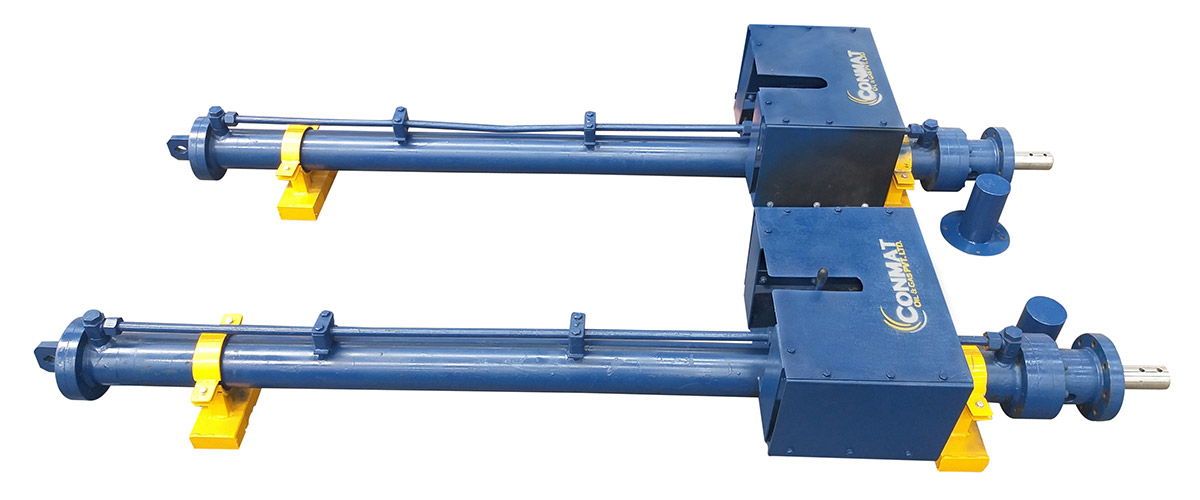

Line Stop Machines

The line stop plugging machine is designed to isolate a pipe section by temporarily blocking the flow in a pipeline by isolating a section of pipe on-stream without shutdown while diverting the product flow using a bypass installed around an isolated section.

The Line Stop Machine consists of Four major parts

Hydraulic Cylinder

A single Hydraulic Cylinder can be used with several sizes of pipeline as per the following list:

| Sr. No. | Model | Travel Length | Plugging Size | MAOP | Temp | ||

|---|---|---|---|---|---|---|---|

| Inch | Mm | Inch | Mm | PSI | °F | ||

| 1 | CM-0406 | 48 | 1220 | 4" - 6" | 100 - 150 | 900 | 180 |

| 2 | CM-0612 | 72 | 1829 | 6” - 12” | 150 – 300 | 900 | 180 |

| 3 | CM-1420 | 102 | 2590 | 14” - 20” | 355 – 500 | 900 | 180 |

| 4 | CM-2234 | 140 | 3556 | 22” - 34” | 558 – 860 | 900 | 180 |

| 5 | CM-3648 | 140 | 3556 | 36” - 48” | 900 - 1220 | 900 | 180 |

Note: For 4” - 6” Jackscrew Cylinder shall be used for Line Stop

Special Equipment available upon request

Hi - Pressure Equipment with a rating of 1440 PSI @ 180 ̊F

Hi - Temperature Line Stop Equipment with rating of 700 PSI @700 ̊F

Plugging Head Housings

Description

Isolation Head

Description

Sealing Element

Description