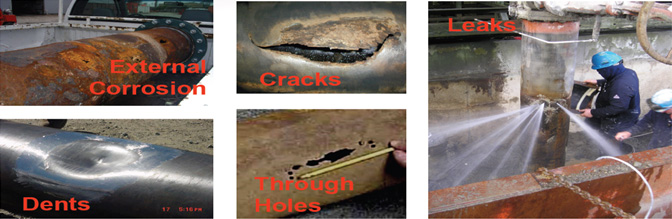

Types of Repairs

Specifications

- Constructed to ASME/ANSI Codes & to ASTM specifications

- Custom designed and manufactured options available for any size, shape, temperature, pressure, or material

- Standard clamps in ½” to 24” sizes for ANSI 150#, 300#, and 600# rate flanges. Larger sizes available upon request

- Seal length:

• For 2” to 12” = 5 inches

• For 14” to 24” = 8 inches

- Temperature range

• For Buna-N seal (-29 deg c to 121 deg c)

• For VITON seal (-29 deg c to 204 deg c)

Advantages

- Welding

Leak Repair Clamps may be seal welded to the pipeline after installation providing the pipe conforms to dimensional tolerances as per pipeline material specifications.

- Quality Control

All Leak Repair Clamps are fully inspected and factory tested to 1.5x Design pressure or as per customer test procedure. Material TCs are available for traceability of material. Third party inspection is possible on request.

- Versatile

Design options such as leak repair body materials, extended seal and body lengths, special sealing materials, etc..

- Site Installation

Leak Repair Clamps are equipped with hinge plates and lifting lungs to simplify field installation.

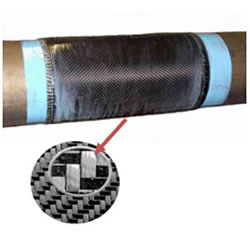

Carbonseal™ Composite System

Specifications

- As per ASME & DOT Carbonseal composite repair system that permanently restores the maximum allowable operating pressure of corroded or damaged pipelines.

Physical Properties

- Compressive, Tensile and Elastic Modulus

- Rupture

- Creep

- Fatigue

- Disbondment and Thermal

Chemical Properties