Line Stop Services

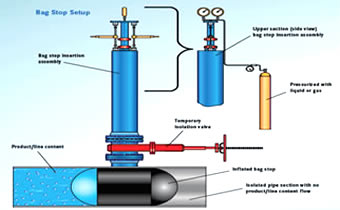

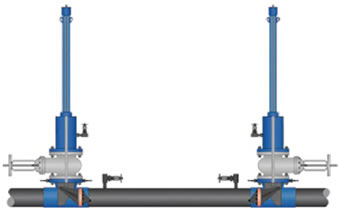

Line stop is the technique of isolation the section of operating pipeline for modification or repair without interrupting line flow with appropriate line stop machines. It is a process of inserting a plugging head into a pipeline for temporarily blocking the flow of product or isolating a section of pipe on stream without shutdown while diverting the product flow using a bypass installed around an isolated section.

“Line stop fitting” is used for such technique along with ConTiTe completion flange & temporary valve called “Sandwich Valve”.

Advantages of Conmat’s Line Stop Services

Provides a better, safer seal on all types of pipe. The ConTiTe completion flange and plug in Conmat’s Line Stop fitting, Unlike other seals which depend on an O-ring alone, Conmat’s completion plug has a metal-to-metal seat backed up by a high temperature O-ring. If re-entry into the pipe is ever required, a safe re-entry and reseal can be made through the same closure flange.

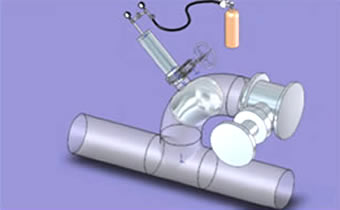

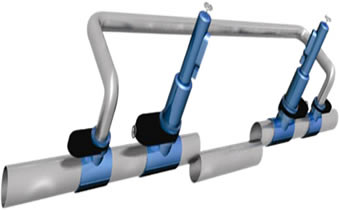

Special Application Line Stopping

Based on your need we develop customised solution for the following applications: